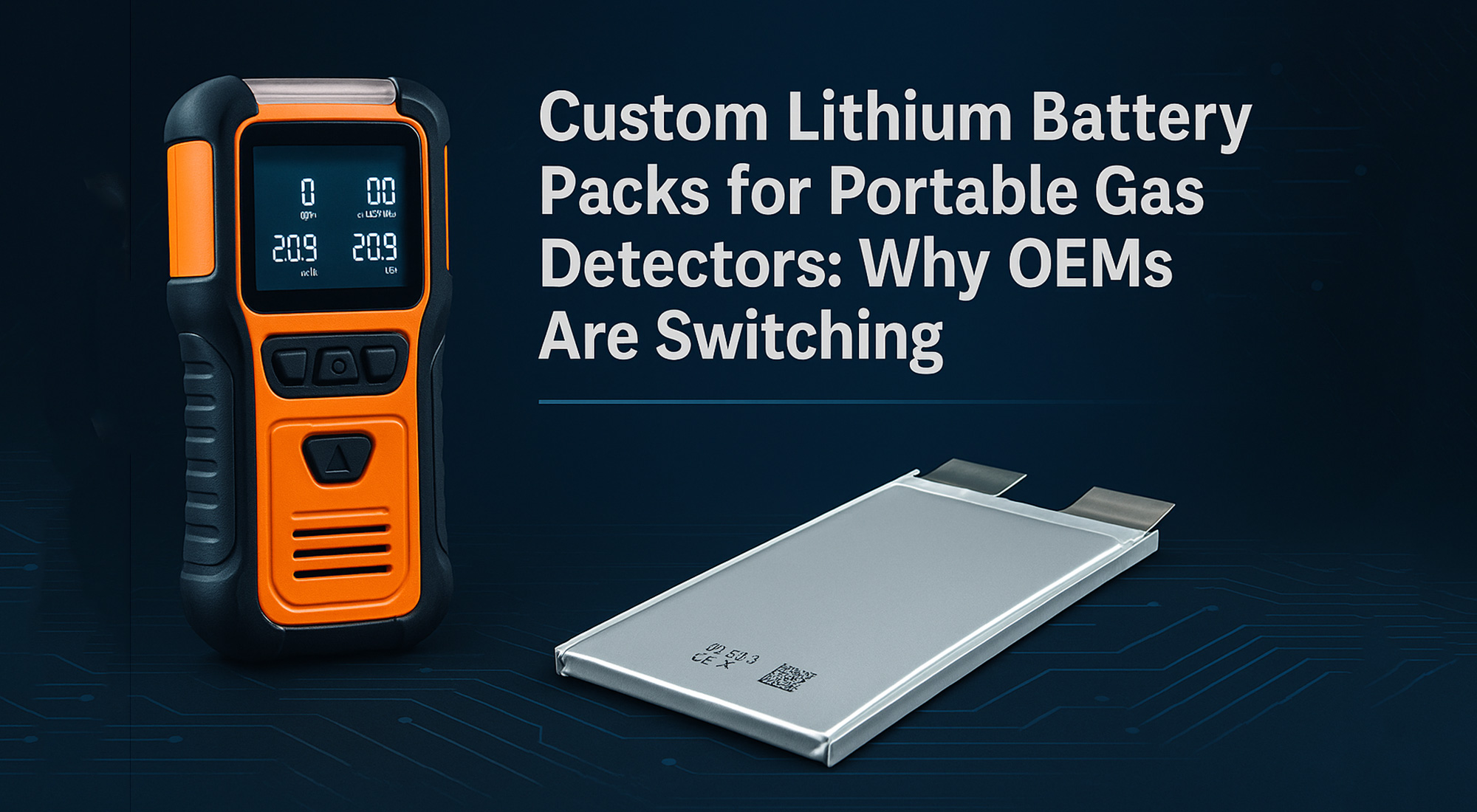

Custom Lithium Battery Packs for Portable Gas Detectors: Why OEMs Are Switching

In the industrial safety and environmental-monitoring market, portable gas detectors are a critical barrier against hazardous atmospheres. OEMs who supply these handheld instruments increasingly demand custom lithium battery packs — offering higher energy density, lighter weight, longer runtime, and better safety than traditional NiMH or disposable cells.

In this post, we explain why the shift is happening, what the battery design challenges are, and how you can work with a partner like PKNERGY to deliver a tailored solution.

⚡ Why Lithium Batteries for Gas Detectors

Many older gas detectors still use NiMH or even alkaline disposables, which add weight, require frequent replacement, and may not deliver sufficient runtime under high-sampling or data modes.

Lithium-ion or lithium-polymer chemistries provide higher energy per volume and weight, enabling smaller form-factor detectors or longer operating time.

Moreover, regulatory contexts reinforce the need for reliable battery backup. For example, in the US state of Maine, the law states that a fuel gas detector “may be battery-operated” if approved by a nationally recognized independent testing laboratory.

Even during lithium-ion battery manufacturing, gas detection systems are essential for monitoring gas build-up, which underscores the connection between safety monitoring and advanced battery design.

🔋 Key Customisation Requirements for Gas Detector Battery Packs

- ⚙️ Voltage & capacity: Many detectors operate at ~3.7V (single-cell) or 7.4V (2S) configurations. Capacity typically ranges from 1,000 mAh to 5,000 mAh depending on instrument runtime needs.

- 🧠 High safety & certifications: For safety-critical devices, compliance with UN38.3 and IEC62133 is essential. PKNERGY’s industrial-grade lithium packs are fully certified.

- 📏 Form factor & mounting: Handheld detectors require slim, robust packs that integrate neatly into compact housings. PKNERGY offers design support for connector types and embedded BMS.

- 🌦️ Environmental robustness: Gas detectors often operate in hazardous or humid zones. The battery must maintain performance between -20°C and +60°C, with IP67-rated protection if needed.

- 🔄 Lifecycle & maintenance: Long runtime and minimal replacements — typically 5–10 years — are critical for industrial customers.

- 🔋 Replaceability & logistics: Many detectors rely on swappable modules. PKNERGY supports safe, easy field-replaceable packs with protective housings.

🏭 Use Case Example & Market Angle

Consider a portable combustible-gas detector used at petrochemical sites. By switching from NiMH to a 3.7V 2,200mAh custom lithium pack, the OEM reduces pack weight by 30%, extends runtime from 8h to 12h, and minimizes charger size.

Meanwhile, the pack meets UN38.3 classification — essential for safe shipping worldwide.

As global safety regulations tighten (e.g., more industrial and residential gas monitoring standards), the demand for certified lithium power solutions for detectors continues to rise.

🔧 How PKNERGY Supports OEM Development

PKNERGY specialises in custom lithium battery pack design for industrial-grade instruments, offering full lifecycle support:

- 🔋 Cell chemistry selection: Li-ion, Li-Po, or LiFePO₄.

- 🧠 BMS & protection board design aligned with IEC62133 standards.

- 🧰 Mechanical structure matching device housing and connectors.

- 🧾 UN38.3 test documentation & logistics classification.

- 🚚 Global delivery — from prototype to certified pack mass production.

✅ Conclusion

The shift toward custom lithium battery packs in gas-detection equipment is driven by performance, weight reduction, safety, and compliance.

For OEMs looking to upgrade or launch a new generation of detectors, a tailored lithium power system ensures operational reliability and long-term value.

Partner with PKNERGY to design, certify, and deliver your next industrial-grade battery solution.

📩 Contact Information

Cassie | PKNERGY Energy Co., Ltd.

Email: sale4@pknergy.com

WhatsApp/Tel: +86 13974604556

🌐 Website: https://pknergypower.com