What are solid-state batteries?

For those interested in the battery industry, the term “solid-state battery” is certainly familiar. This new technology is considered an upgrade to lithium batteries, capable of significantly enhancing the current battery life by several times.

Especially in the electric vehicle industry, solid-state batteries are seen as the key to revolutionizing the sector. Imagine an electric car that can run for 1000 km and only takes fifteen minutes to fully charge—how enticing is that?

This potential has led to intense competition among all battery manufacturers in this field. So, what makes solid-state batteries so magical? Please read the following article for a comprehensive understanding of solid-state batteries.

What is a Solid-State Battery?

The concept of the solid-state battery was first introduced by British scientist Michael Faraday. However, for over a century, solid electrolytes seemed to fade from the stage of history, disappearing from human view. Entering this century, humanity quietly picked up where Faraday left off more than 100 years ago, embarking once again on the exploration of solid electrolytes.

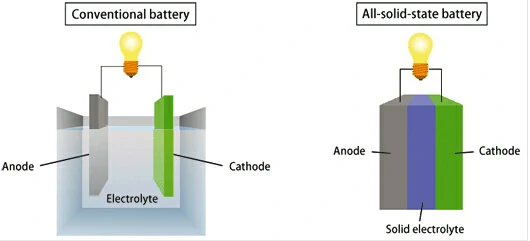

The biggest difference between solid-state batteries and lithium batteries is the SSB absence of liquid or gel electrolytes. Instead, solid-state batteries use glass compounds made of lithium or sodium as solid electrolytes, through which lithium ions migrate. In solids, ionic conductivity is relatively high, and the risk of leakage and gas production is minimized, thereby enhancing the safety and energy density of the battery.

Why Develop Solid-State Batteries?

In the battery industry, liquid lithium batteries, whether lithium iron phosphate or ternary lithium batteries, are considered to have reached their “limits.” It has become increasingly difficult to achieve new breakthroughs in technology. This means that to obtain higher capacity batteries with smaller volumes, new technologies must be developed.

At the same time, solid-state batteries can fundamentally address the major safety hazards of lithium-ion batteries. Traditional lithium-ion batteries can self-ignite or explode due to the flammable and volatile organic electrolytes they contain.

Moreover, issues such as electrolyte corrosion, volatilization, and leakage can pose serious safety risks to the battery system. Solid electrolytes, on the other hand, are inherently non-flammable, heat-resistant, non-corrosive, and non-volatile. They offer better mechanical strength, thermal stability, and electrochemical stability compared to traditional electrolytes, thereby significantly enhancing the safety of the battery.

Three Mainstream Paths for Solid-State Batteries

Solid-state batteries primarily follow three technological paths: polymer, oxide, and sulfide. The cathode materials and paths of solid-state batteries do not differ significantly from those of liquid lithium batteries. The different technological routes are mainly distinguished by the types of electrolytes used. Based on the electrolytes, solid-state battery paths can be divided into three categories: polymer, oxide (film or non-film), and sulfide, each with its own advantages and disadvantages.

A. Polymer

Advantages:

-

- Easy to process, and existing liquid electrolyte production equipment and processes can meet the production and research needs.

Disadvantages:

-

- Low conductivity, requiring heating to 60 degrees Celsius to function properly.

- Poor stability, incompatible with high-voltage cathode materials, and prone to catching fire at high temperatures.

- Narrow electrochemical window, with the electrolyte easily decomposing at high voltage differences (>4V).

B. Sulfide

Advantages:

-

- Highest conductivity and a wide electrochemical stability window (above 5V), making it the most promising for development.

Disadvantages:

-

- Poor thermal stability, with the thermal reaction starting at a temperature range of 400−500°C.

- Complex preparation process and prone to reacting with water and oxygen in the air to produce highly toxic hydrogen sulfide gas.

C. Oxide

Advantages:

-

- Good conductivity and stability, higher ionic conductivity than polymer, thermal stability up to 1000 degrees Celsius, and excellent mechanical and electrochemical stability.

Disadvantages:

-

- Lower conductivity compared to sulfides.

- Issues with rigid interface contact.

Currently, the research directions of various battery manufacturers differ. China and the United States mainly focus on oxide paths while simultaneously exploring new routes. Japanese companies, such as Honda, tend to favor the sulfide path. Due to the relatively lower research costs and difficulty, several semi-solid-state batteries have seen commercial applications in the oxide system by 2024. However, from a long-term perspective, despite the high research difficulty, the sulfide solid electrolyte, with its excellent performance and significant potential, continues to attract substantial investment and research efforts from well-capitalized battery companies.

Three Mainstream Paths for Solid-State Batteries

Advantages of Solid-State Batteries

High Energy Density:

With the use of all-solid-state electrolytes, the applicable material system of lithium-ion batteries changes significantly. A key change is the elimination of the need for lithium-intercalated graphite anodes. Solid-state batteries can use lithium metal as the anode material. The theoretical specific capacity of lithium metal is 3860 mAh/g, compared to only 372 mAh/g for the graphite anode in traditional lithium-ion batteries. This allows batteries to surpass the chemical limitations and achieve higher performance levels.

Smaller Volume:

Traditional lithium-ion batteries require separators and electrolytes, which together occupy nearly 40% of the battery’s volume and 25% of its mass. By replacing them with solid electrolytes (primarily organic and inorganic ceramic materials), the distance between the positive and negative electrodes (traditionally filled by separators and electrolytes, now filled by solid electrolytes) can be reduced to just a few to tens of microns. This means the batteries can be made smaller, making solid-state battery technology a crucial step towards battery miniaturization.

High Plasticity:

Using ceramics as solid electrolytes has the advantage of exhibiting surprising plasticity when thin, despite ceramics being fragile in everyday contact. Even after hundreds of bends or folds, the battery’s capacity, charge-discharge efficiency, and lifespan remain largely unchanged. This means that solid-state batteries can be made into any shape, offering more design flexibility for electronic devices, potentially leading to innovative shapes and structures and driving technological product innovation.

Enhanced Safety:

In traditional lithium-ion batteries, using lithium metal as the anode material can lead to dendrite formation during charging and discharging. Dendrites are needle-like or tree-like structures formed by uneven deposition of lithium metal in the electrolyte. These dendrites can grow and potentially penetrate the separator, causing direct contact between the positive and negative electrodes, leading to short circuits and possibly fires or explosions.

Additionally, the organic liquid electrolytes in traditional batteries are prone to side reactions, oxidation, gas production, and combustion at high temperatures. Solid materials can completely avoid these issues.

Better High and Low-Temperature Performance:

The operating temperature range of currently announced solid-state batteries is -20°C to 105°C. Lithium-ion battery electrolytes use flammable organic solvents, posing risks in high-temperature environments. All-solid-state battery electrolytes do not use flammable materials, making them suitable for use at higher temperatures.

In low temperatures, ion mobility in liquid electrolytes can become sluggish, reducing battery performance and voltage. Solid electrolytes do not freeze like liquids, so internal resistance changes are minimal, maintaining better performance at low temperatures.

Comparison of Lithium-Ion Batteries and Solid-State Batteries

| Feature | Lithium-Ion Battery | Solid-State Battery |

|---|---|---|

| Energy Density | 150-250 Wh/kg | 250-500 Wh/kg |

| Electrolyte Type | Liquid or Gel Electrolyte | Solid Electrolyte |

| Safety | Risk of leakage, fire, and explosion | Lower risk, more stable |

| Operating Temperature | -20°C to 60°C | -30°C to 100°C |

| Cycle Life | 500-1000 cycles | 1000-3000 cycles |

| Cost | Relatively low | Currently high |

| Manufacturing Complexity | Established processes | Complex, less established |

| Commercial Availability | Widely available | Limited, in development |

Three Mainstream Paths for Solid-State Batteries

QuantumScape

Company Background: QuantumScape was founded in 2010 and is led by President and CEO Dr. Jagdeep Singh. The company is headquartered in San Jose, California, and operates in both the U.S. and Japan.

Technology: QuantumScape focuses on oxide technology. Their solid-state battery is unique in that it doesn’t pre-set an anode material. When charging, pure lithium metal transforms into lithium ions that migrate to the other side of the battery to form the anode, a technique they call “anodeless.” This is made possible by their patented ceramic material used for the battery separator, which allows lithium ions to move freely while preventing lithium metal from reacting with the cathode material and forming dendrites.

Advantages: QuantumScape has created over 200 patents and applications. Their patented solid-state ceramic separator, combined with organic liquid electrolytes (catholyte), allows for custom catholyte materials better suited for the cathode’s voltage and transmission requirements.

Latest Progress: On March 27, 2024, QuantumScape began delivering Alpha-2 prototypes to customers.

Solid Power

Company Background: John Van Scoter has served as CEO and President since June 2023. Solid Power has partnerships with BMW and Ford and is headquartered in Louisville, Colorado.

Technology: Solid Power’s focus is on sulfide technology, powered by their proprietary sulfide-based solid electrolyte. The cathode material is NMC, and the company has two battery technologies using different anode materials: one with high silicon content and another with lithium metal.

Advantages: Solid Power’s key component is their sulfide-based solid electrolyte, which provides an optimal combination of conductivity, manufacturability, and battery-grade performance.

Latest Progress: On January 16, 2024, Solid Power signed a new agreement with SK to deepen their partnership.

Dyson (Sakti3)

Company Background (Dyson): Dyson is a British technology company specializing in household products, with an invention team of 1200 scientists and engineers. Dyson started its in-house battery program over a decade ago.

Company Background (Sakti3): In 2015, Sakti3 was acquired by Dyson Ltd. Sakti3 was co-founded in 2007 by Dr. Ann Marie Sastry, Dr. Chia-Wei Wang, and Dr. Fabio Albano as a spin-out from the University of Michigan.

Technology: Sakti3 uses thin-film deposition technology, typically used in photovoltaic solar cells. Their solid-state batteries have no liquid electrolytes, instead using a “sandwich” structure to ensure normal ion transmission.

Advantages: Dyson has revealed that Sakti3’s solid-state batteries can achieve an ultra-high energy density of 550 Wh/kg, nearly doubling the maximum energy density of 300 Wh/kg for ternary lithium batteries.

Latest Progress: On June 16, 2023, Dyson announced plans to open an advanced manufacturing plant for next-generation batteries in Singapore.

Toyota

Company Background: Toyota has been working on solid-state battery development since 2006, focusing on sulfide technology. They hold over 1300 solid-state battery patents and are headquartered in Tokyo, Japan.

Technology: Toyota’s disclosed information indicates a focus on sulfide technology.

Advantages: Toyota holds 1331 solid-state battery-related patents, covering battery structure, material applications, and manufacturing processes, making them the company with the most related patents worldwide. They plan to begin commercial production between 2026 and 2027.

Latest Progress: On June 13, 2024, Toyota announced a technological breakthrough that addresses the long-standing challenge of battery durability.

Ampcera

Company Background: Ampcera is headquartered in Silicon Valley, California, and was founded in 2017. The CEO is Dr. Sumin Zhu.

Technology: Ampcera’s ASSB technology comprises IP-protected sulfide solid electrolyte materials designed for ultra-fast charging. They use high-capacity NMC cathodes and silicon-based anodes to achieve a target energy density of 400 Wh/kg.

Advantages: Ampcera’s all-solid-state battery (ASSB) technology has achieved fast charging from 0 to 80% state of charge (SOC) in 15 minutes at a peak C rate of 4C.

Latest Progress: On February 25, 2024, Ampcera’s all-solid-state battery technology surpassed the U.S. DOE’s extreme fast-charging goal of 80% charge in 15 minutes.

Samsung SDI

Company Background: Samsung SDI is headquartered in Yongin, Gyeonggi-do, South Korea, and the CEO is Yoon Ho Choi.

Technology: The company focuses on sulfide electrolytes, using an Ag-C composite anode without excess lithium. The Ag-C layer effectively regulates lithium deposition, achieving long electrochemical cycle life.

Advantages: Samsung SDI’s Super-Gap solid-state battery technology has an energy density of 900 Wh/L, about 40% higher than their current lithium-ion batteries. They claim the ability to charge a prismatic cell from 8% to 80% in 9 minutes. Mass production is planned for 2026.

Latest Progress: In March 2024, Samsung SDI announced plans to start mass production of solid-state batteries for electric vehicles and other applications by 2027.

Chinese Manufacturers

Chinese battery manufacturers are more discreet, but it’s known that BYD and CATL are developing solid-state batteries. Globally, there are 20,798 key technology patent applications for solid-state batteries, with China accounting for 7640, or 36.7%. Over the past five years, China’s annual growth rate in solid-state battery patent applications has been 20.8%, the highest in the world.

Opinions on Solid-State Batteries from Other Industry Leaders

Challenges of Solid-State Batteries

High Cost

For the sulfide route, the cost of sulfide solid electrolytes currently exceeds $195 per kilogram, much higher than the $50 per kilogram needed for commercialization. This issue stems from the high cost of lithium sulfide (not less than $650 per kilogram) required for synthesizing sulfide solid electrolytes. Additionally, the high-performance materials (such as high-purity ceramics) and complex manufacturing processes used in solid-state batteries make their costs significantly higher than traditional lithium-ion batteries.

Production Difficulties

If using the sulfide solid electrolyte route, production is challenging due to the electrolyte’s tendency to react with moisture and oxygen. This necessitates a highly controlled production environment, ideally in an inert gas-filled sealed chamber.

Low Ionic Conductivity

In solid-state batteries, the interface contact between the electrode and the electrolyte changes from solid-liquid to solid-solid contact. Compared to liquid electrolytes, the contact area between solids is smaller, resulting in higher interfacial resistance. Additionally, solid electrolytes contain many grain boundaries, which often have higher resistance than the bulk material, hindering lithium-ion transport between the electrodes and negatively impacting fast-charging performance and cycle life.

Poor Cycle Life

The solid-solid contact in solid-state batteries is more rigid, making it more sensitive to volume changes in electrode materials. During cycling, this can lead to poor contact between electrode particles and between electrode particles and the electrolyte, causing stress accumulation, electrochemical performance degradation, and even cracks, which can rapidly decrease capacity and lead to poor cycle life.

When Will Solid-State Batteries Be Available?

As of July 2024, there are no truly commercially available all-solid-state batteries. Chinese car manufacturers claiming to use solid-state batteries are actually using semi-solid-state batteries with reduced liquid content. Similar to lithium batteries, which took decades to transition from technological inception to widespread use, many experts believe that solid-state batteries require even longer periods for validation and technological breakthroughs.

However, the wait may not be indefinite. The significant potential of solid-state batteries has spurred intense competition, accelerating progress in the field. Many manufacturers have targeted 2027 as the year for commercializing solid-state batteries. Let’s keep an eye on the developments as the industry moves toward this ambitious goal.

Save Money, Protect Environment

PKNERGY helps you reduce your energy bills for your home solar energy storage, store your solar energy for use anytime- at night or during an outage.