What is the difference between a semi solid state battery and a solid-state battery?

What is a semi-solid-state battery?

Semi-solid-state batteries use a hybrid design of solid electrolyte and liquid electrolyte. The electrode on either side of the battery does not contain liquid electrolyte, and the electrode on the other side contains liquid electrolyte.

The ratio of solid electrolyte to liquid electrolyte is not one to one, but is divided according to the proportion of liquid electrolyte in the battery cell: liquid (25wt%), semi-solid (5-10wt%), quasi-solid (0-5wt%) and all-solid (0wt%)

Compared with existing lithium-ion batteries, semi-solid batteries are small in size, more stable and safe, can achieve higher energy density, and are much cheaper than lithium-ion batteries.

What is the difference between semi solid state battery and all solid state battery?

Semi solid state battery is not all solid state battery. All solid state battery is 100% free of liquid electrolyte. Although semi solid state battery and solid state battery are similar in principle, there are significant differences between them:

Electrolyte materials

Semi-solid batteries: use a combination of partially solid electrolytes and partially liquid electrolytes. The solid electrolyte is usually a ceramic or polymer material, while the liquid electrolyte is a traditional liquid electrolyte. This combination can improve the ionic conductivity and interfacial stability of the battery.

All-solid batteries: use solid electrolytes completely without liquid components. Solid electrolytes can be ceramics, polymers or other solid materials, with high stability and safety.

Safety

Semi-solid batteries: Compared with traditional liquid electrolyte batteries, safety is improved because partially solid electrolytes can reduce the risk of leakage of liquid electrolytes. However, since it still contains liquid components, its safety is not as good as that of all-solid batteries.

All-solid batteries: Since solid electrolytes are used completely, the risk of leakage and combustion of liquid electrolytes is eliminated, and safety is the highest.

Energy density

Semi-solid batteries: have a higher energy density because partially solid electrolytes can improve the overall stability and charge and discharge efficiency of the battery, but since it still contains liquid components, the energy density is not as high as that of all-solid batteries.

All-solid batteries: Since solid electrolytes are used completely, higher energy density can be achieved, and the potential energy density far exceeds that of traditional liquid electrolyte batteries and semi-solid batteries.

Manufacturing and cost

Semi-solid-state battery: The production process is relatively simple, because part of the manufacturing process can be used in the existing liquid electrolyte battery production line, so the cost is lower than that of all-solid-state battery.

All-solid-state battery: The manufacturing process is complex and the technology is difficult. The current production cost is high, but with the advancement of technology and large-scale production, the cost is expected to decrease.

What are the benefits of semi-solid batteries?

1. High energy density

The upper limit of the energy density of liquid lithium-ion batteries is generally recognized to be around 300Wh/kg-400Wh/kg. The theoretical energy density of solid-state batteries is as high as 700Wh/kg, almost double the current most advanced lithium battery data.

2. Overcoming the temperature attenuation problem

Solid electrolytes are used in semi-solid batteries, and solid electrolytes will not affect battery performance due to low temperatures. This effectively solves the problem of battery life discount in winter for pure electric vehicles.

3. Higher safety

Semi-solid batteries or solid-state batteries have no liquid substances, or the liquid substances are greatly reduced. Therefore, when damage or puncture occurs, it will effectively avoid spontaneous combustion or explosion.

4. Longer service life

According to available data, the current semi-solid-state battery has a capacity retention rate of more than 85% after 2,000 cycles at room temperature. Under the same conditions, ordinary liquid batteries have a capacity retention rate of only about 80% after 1,200 cycles.

Where does semi-solid-state battery technology come from?

Semi-solid-state technology is more like a mid-term product in the research of all-solid-state batteries. Solid-state batteries still have many problems in terms of scale, commercialization, and cost.

Many battery companies choose to speed up the research and development of semi-solid-state batteries first. Despite this, there are still some people who believe that solid-state batteries will eventually be difficult to commercialize, and semi-solid-state batteries are already the ultimate solution for electric vehicles.

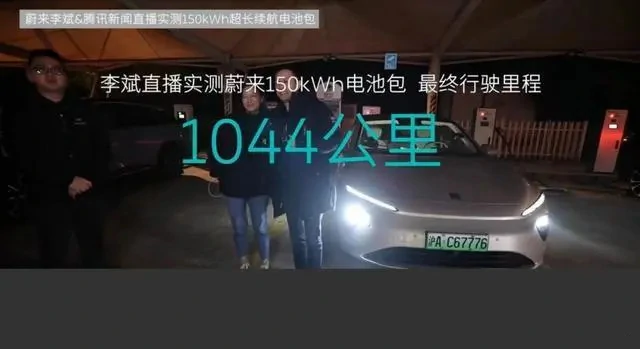

On December 17, 2023, NIO live-streamed the use of a 150kwh semi-solid-state battery to complete a 1,000km range challenge.

According to the currently published technical information, the solid electrolyte used in solid-state batteries relies on rare metals and complex processes, which is the key reason affecting the cost.

Semi-solid-state batteries differ from mature lithium batteries in only about 20% of the process. They are based on the transformation of existing battery production lines and can be mass-produced faster. Therefore, in terms of economic efficiency and industrialization speed, semi-solid-state technology is currently the best for enterprises.

How Semi-Solid-State Batteries Work

Like all batteries, semi-solid batteries release current through chemical reactions between positive and negative electrode materials. Semi-solid batteries usually have electrolytes that are closer to gel. In traditional lithium batteries, the positive and negative electrodes are “energy warehouses”, and the electrolyte is like a “channel” that allows lithium ions to move freely between the positive and negative electrodes. Therefore, it is also called a liquid battery.

Semi-solid batteries have made innovations in electrode materials. They use “mud” formed by mixing fine lithium compound particles with liquid electrolyte as electrode materials. This hybrid design allows the battery to maintain the high safety of solid-state batteries while also having the high ion transmission rate of liquid batteries.

Is semi-solid already commercially available?

Some companies have started small-scale production and applied it to consumer electronics and electric vehicles.

For example, the Chinese car brand Zhiji launched a semi-solid-state battery this time. According to the official description, the battery contains both solid electrolytes and liquid electrolytes.

In fact, Zhiji is not the first new energy vehicle company to install semi-solid-state batteries. At the end of last year, NIO conducted a live long test of the NIO ET7 equipped with a 150kWh semi-solid-state battery, and the actual range exceeded 1044km.

However, there are still no applications that use semi-solid-state batteries that can be purchased. Only in April 2024 did NIO launch a 150kwh semi-solid-state battery rental event.